External Hex Platforms with fractured screws: best plan?

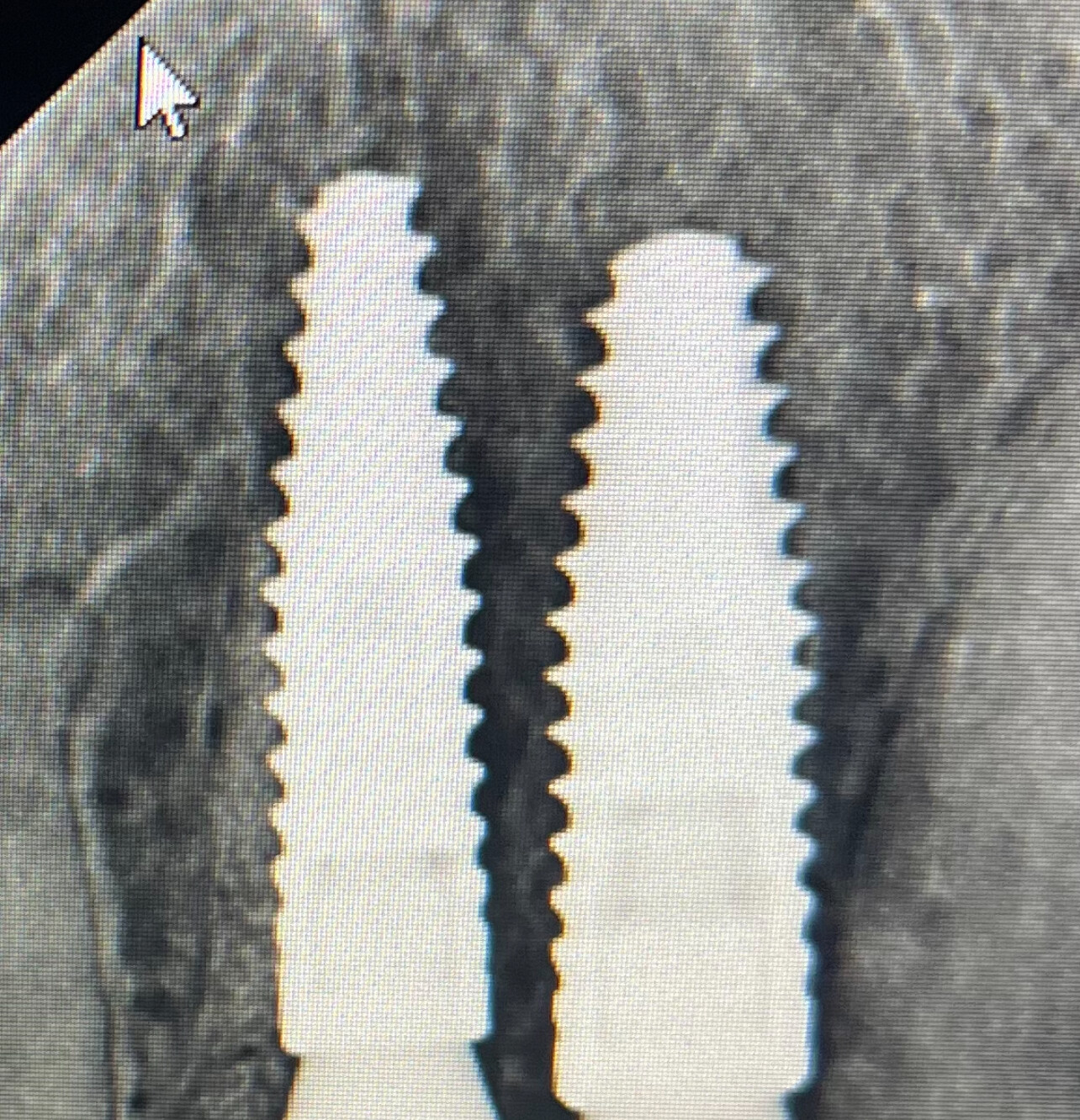

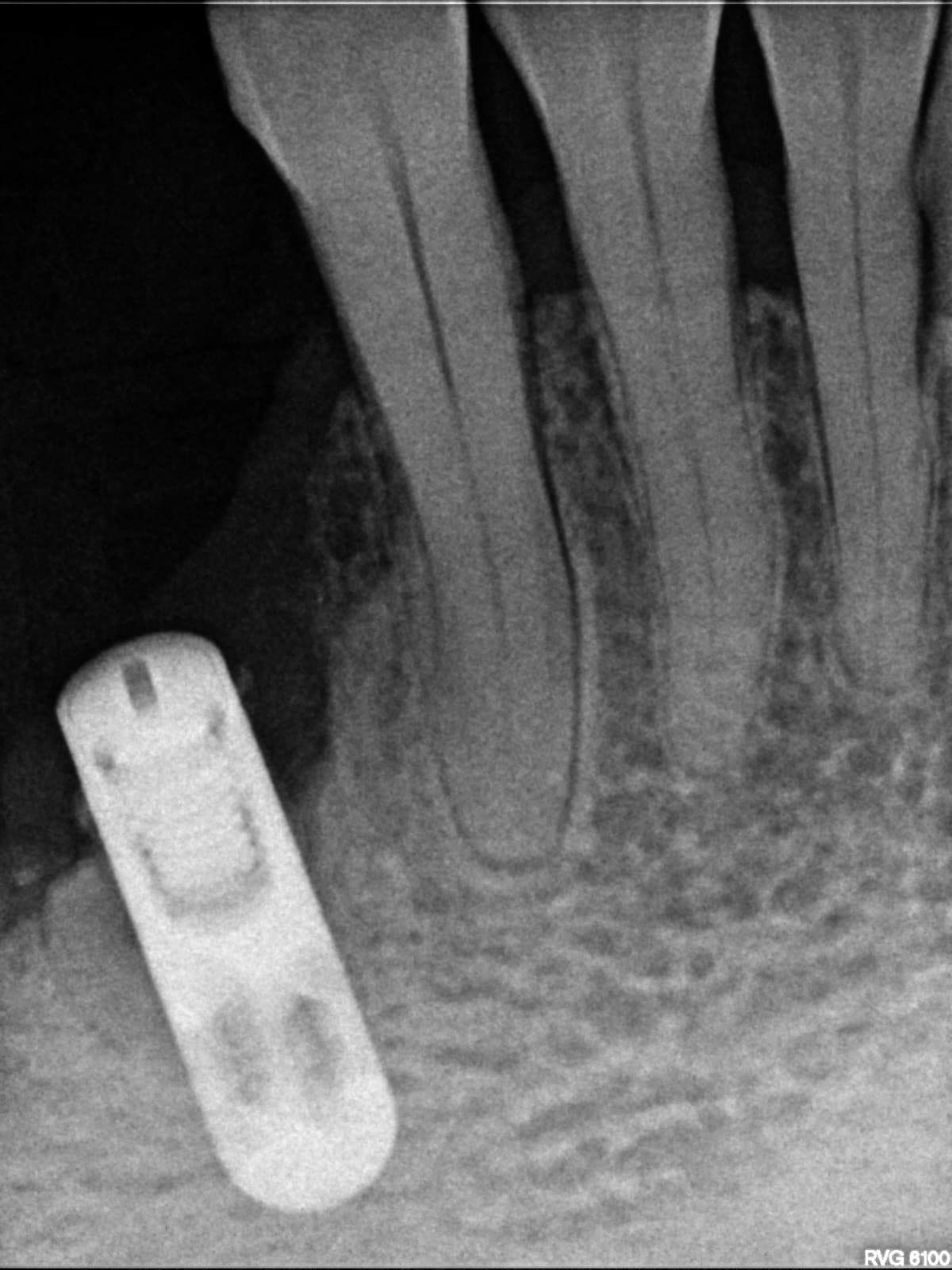

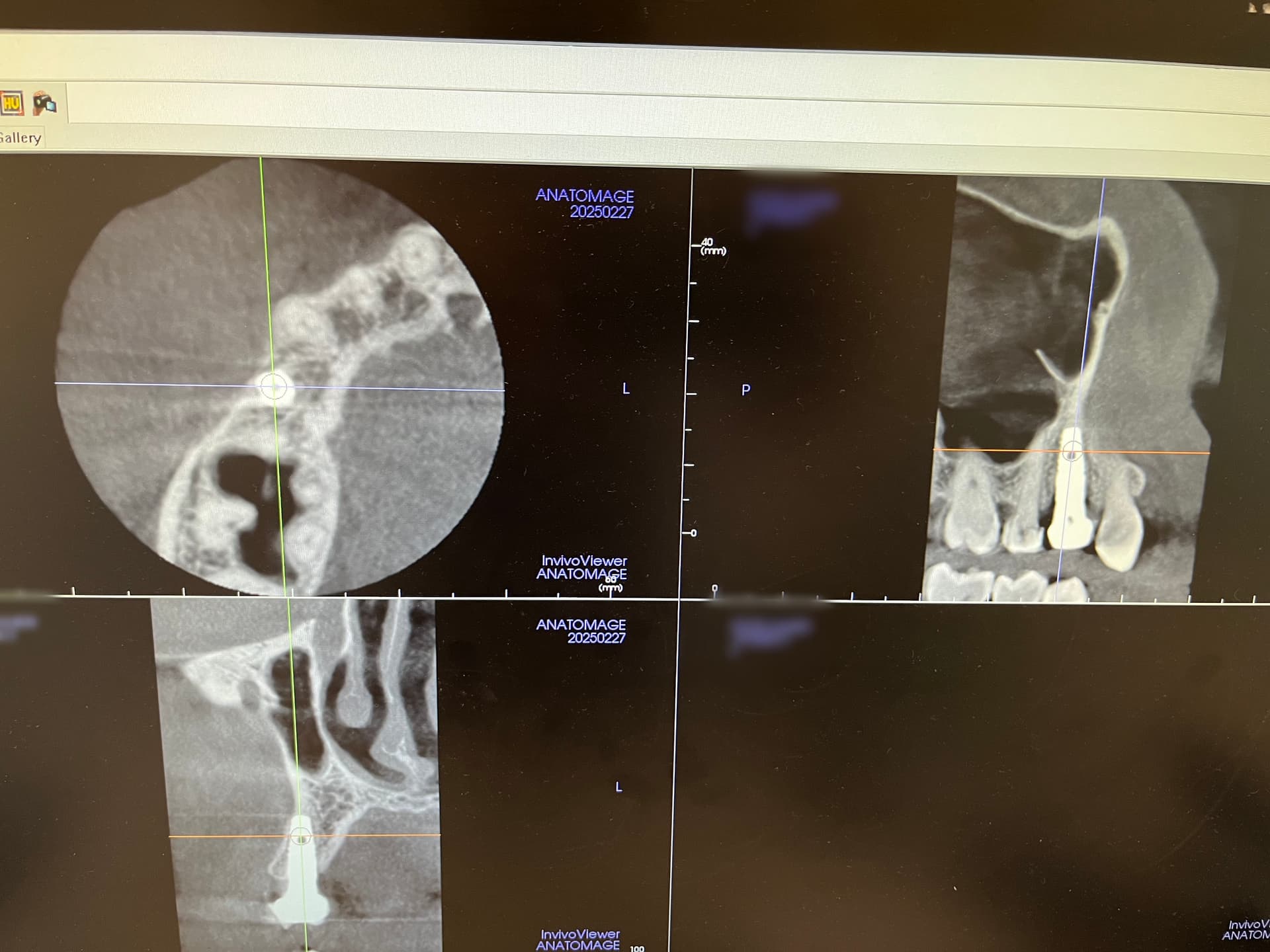

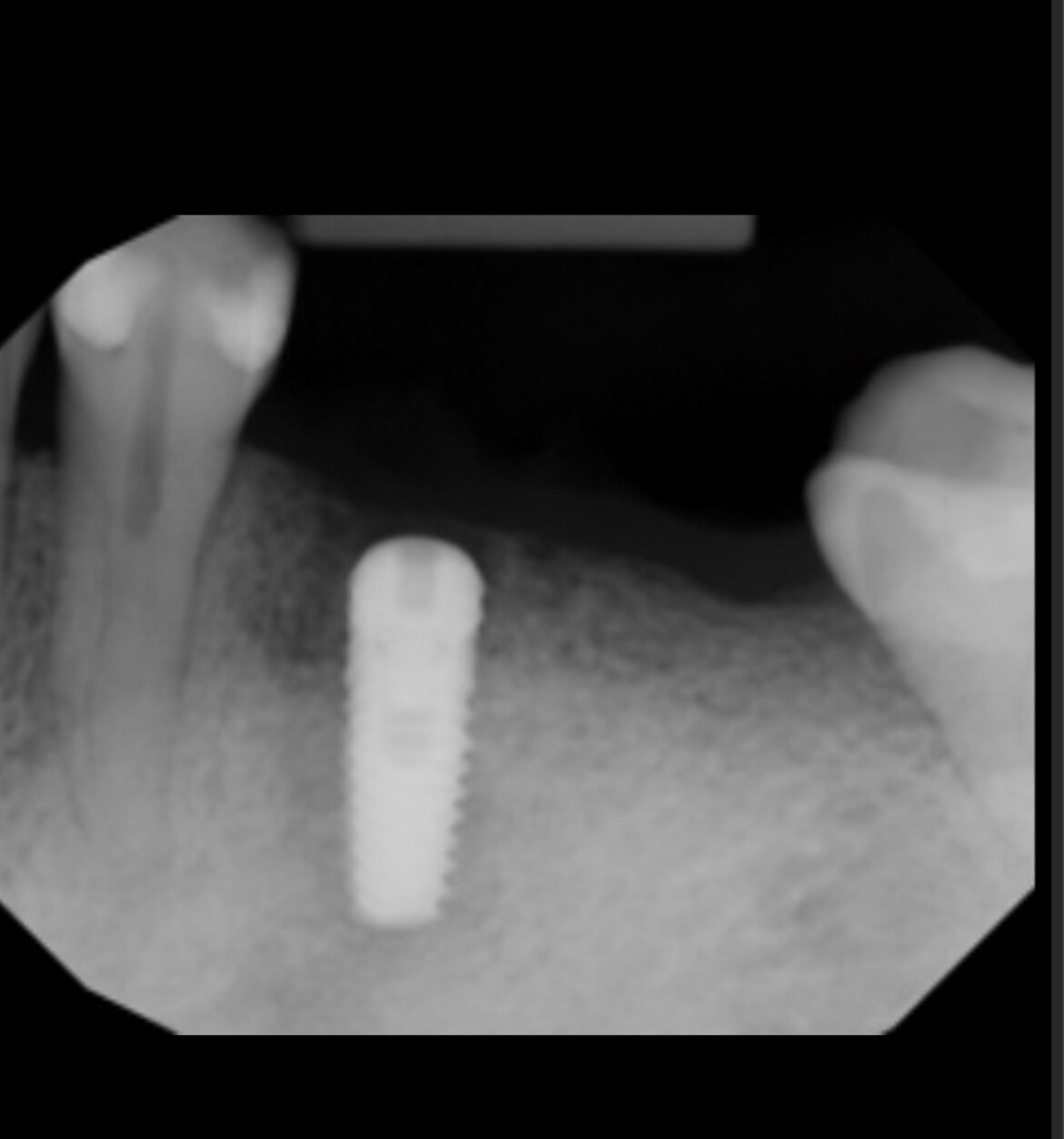

I have a patient who presented with an implant supported fixed partial denture #12-14 [maxillary left first premolar to first molar; 24-26]. The fixed partial denture has #12 and #13 [maxillary left second premolar; 25] as splinted double abutments and #14 is a distal cantilevered pontic. The 2 abutments have external hex platforms with fractured screws. I am pretty sure I can get the broken screws out but can I still get parts to do a new screw retained post? Does anyone recognize the implant? Has anyone done a reverse custom post to fit a bridge? Patient also has financial constraints. Thoughts on this case?

15 Comments on External Hex Platforms with fractured screws: best plan?

New comments are currently closed for this post.

Rateb SADEK

1/11/2014

According to the website www.whatimplantisthat.com it is appear to be Biomate 3i

OSSEOTITE Parallel Walled 4.mm

mike ainsworth

1/11/2014

those look like external hex 3i implants to me.

to fabricate a reverse abutment you need the ucla abutments trim them so they are passive when seated and the bridge is in situ, (bridge will rattle a bit). set the bridge to the opposing with a duralay seating jig.

Make sure there are no undercuts in the fit side of the bridge otherwise this is the bit where it can all go wrong, if unsure, wax a fine film of die spacer wax inside. otherwise petroleum jelly.

seal the screw holes in the uclas after screwing them down hand tight, liquid duralay into the bridge and seat making sure its located into your placement jig on the opposing. allow to go to dough stage and make sure you unseat and re seat a little. keep it moving just in case it locks. allow to harden, carve orientation and number marks, trim up and then send off to be cast.

hope this helps.

Ezgator

1/11/2014

Thanks sounds like a plan

ttmillerjr

1/12/2014

No, I think they're Nobel. It would be a good idea to make 2 new splinted crowns (eliminate the cantilever). The external hexes have enough trouble without making "reverse abutments". Why take a chance trying to keep the bridge? You have a higher risk of failure and the bonus of making no money. And yes Nobel can provide the parts you need.

michaelwjohnson dds, ms

1/14/2014

Those are either nobelbiocare or 3i implants. Simply prep an access hole in the crowns to get the screwhead out of the crown, remove the fractured screw shank and replace the screws. This turns the restoration into a screw retained prosthesis. You may want to check the occlusion on the cantiliver to make sure it's light so to decrease the risk of fracture in the future

kewx

1/14/2014

The implants are the type that are supposed to be countersunk. They do not appear to be Zimmer''s spline.

Mark Montana

1/14/2014

Mike's technique is sound and I've done similar a few times. That said, these are old implants with an old restoration made elsewhere so I strongly recommend starting fresh with new splinted crowns sans the cantilever pontic as TT suggests. Whether Nobel or 3i, the ex hex is the same.

Alejandro Berg

1/14/2014

This are Branemark compatible external hex, and that means it will be very easy to get parts. You have 3 choices, since this happens quite often with distal cantilevers over external hex, you can make a 2 unit fpd and sleep easy for ever, risk a new 3 unit cantilever (once failled will probably fail again) or place a pterigoid implant and make a 4 unit fpd or a 3 unit fpd with a shiny distal connector and that will also allow you to be quite relaxed. Remember that patient´s financial constraints should not be of your concern while planning a case, You should present the case as it should be done, most likely the patient had the same constraints the first time arround and that is why you are dealling with broken screws now.

cheers

Carlos Boudet, DDS

1/14/2014

The implants are probably Nobel.

Two other implant companies that manufacture these external hex implants and have parts available for them are 3i and Keystone (Lifecore Dental originally).

Sterngold and Imtec also made them but have discontinued support for them.

Make sure you explain to the patient that the large molar cantilever is probably the reason that the very nicely done bridge has failed by creating a mechanical overload on the screws.

If the patient has financial constraints, consider restoring only the two premolars.

Good luck!

Keith

1/14/2014

Assuming this is a cement retained fpd cantilever, one option is to give the fpd with fractured abutments to a lab technician to heat up the prosthesis and desicate the cement so the abutments will separate from the fpd. Replace the abutment screws and recement the prosthesis.

The key is to heat up the fpd slowly and not to hot to cause the porcelain to fracture off the framework.

don22

1/14/2014

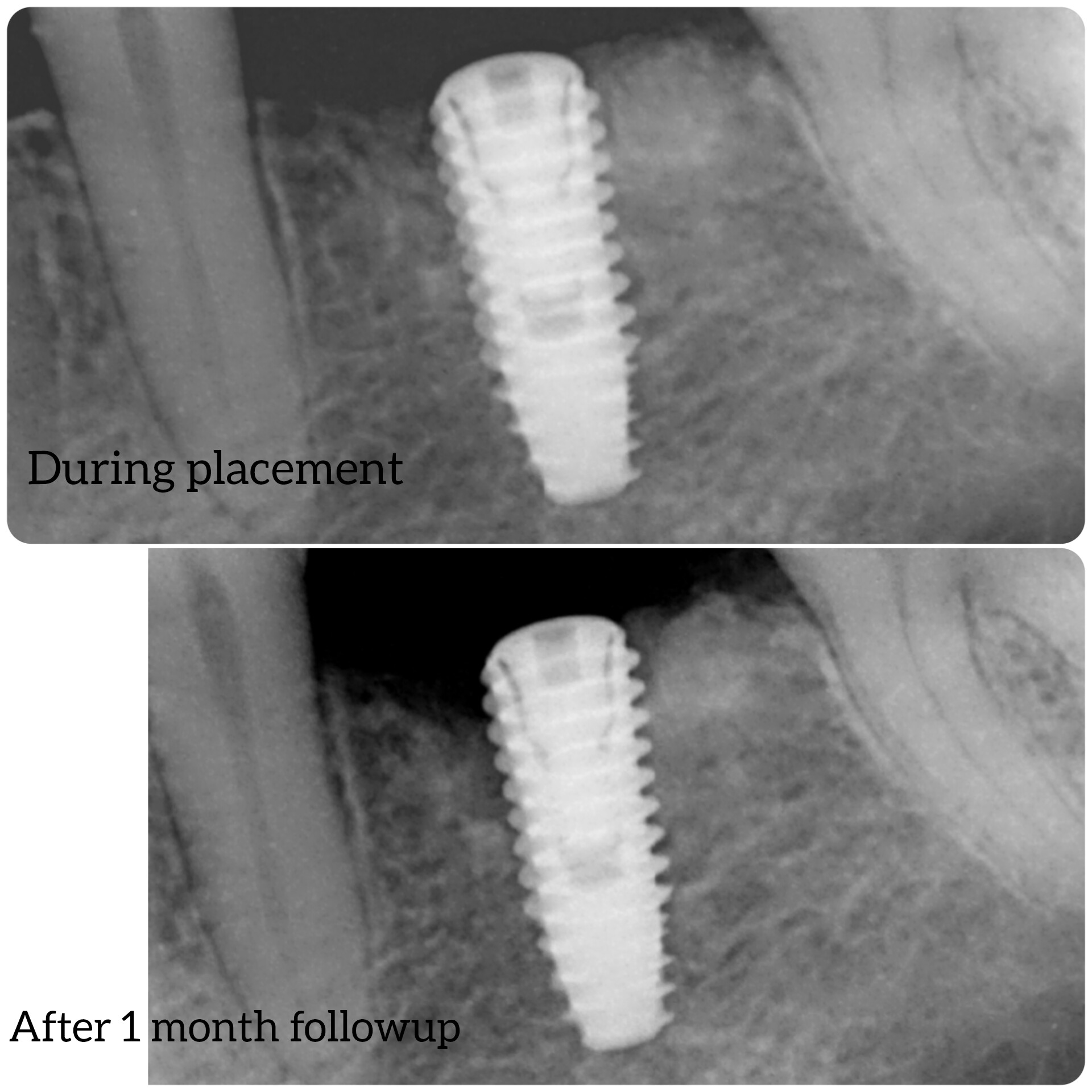

Looks like the first implants on the market. Branemark, 3I or Corvent. The broken screw is easy to "unscrew" (remove). Implants appear well integrated so it should be possible to remake a screw retained, double abutted three unit bridge. Check the occlusion.

Ezgator

1/14/2014

I attempted to unscrew 2 no luck. I had to drill it out. Do the top few threads are no good. I was able to screw in a prefab abutment on 13 but not on 12. So I plan on making a custom post on 12 and splinting it all to 11( with a stress breaker).

Dr. TK

1/14/2014

I send identification reqests to Darwin at Attachments International. He identifies the implants and often has the parts that I need. I would also ask him if a tap is available for this particular implant to repair the damaged threads.

I lean towards the approach proposed by michaelwjohnson, except I would cut off the potic and seat it as two units.

I avoid splinting implants to natural teeth (but I don't speed on the freeway either). I understand that opinions on this topic vary.

Dr Bob

1/15/2014

I have tried, with rather good results, using an end cutting bur and contacting the broken surfaceof the screw to back it out. If the fractured surface is to smooth it can be roughened with a small bur. The end cutting bur can be used by hand or in a low speed contra angle. This type of bur has a cutting surface only on the end of the bur and will not mess up the screw threads if used with care.

If you have destroyed the threads inside the implant there may be enough metal left to retap and still screw an abutment into place. Talk to your lab about taps as they may have one for this implant.

If you want to reuse the old bridge narrow the occusal surface and remove as much as you can any contact that is not along the long axis of the implants. The pontic must be as narrow as it can be made and be slightly out of occusion. Do try to salvage the abutments. Your lab may be able to help to separate the bridge from the abutments. Do not reuse the old screws in a case like this. Stronger screws may be available for these implants. I remember a case a few years back when I found screws with a square socket that required a bit more torque and were less likely to loosen. If you can eliminate the pontic do so. If the patient really wants that tooth there then place another implant, or warn of increased risk of failure.

mpedds

1/15/2014

Micro-movement is a cause of fatigue and screw fracture. I would not recommend re-using the old bridge. Start over. These are most certainly Branemark style external hex implants. Nobel bought out Steri-oss years ago and have all the parts. Their technical support is good and will walk you through everything you need.